I shared on Twitter not long ago, “The good news is I got a grant! The bad news is I got a grant!” There is too much truth in that dichotomy, but in spite of all the extra work and rules and policies and bids and other “red tape” to be dealt with to purchase the supplies and organize the classes … this is an awesome opportunity for all concerned.

The grant requirements demanded a focus on middle and high school teachers and students, computer programing, and a STEM learning emphasis. You’ll note by the name of the grant (see the title of this post) that the grant department folks that helped in editing, implored me to mention as many aspects of the program as possible in the title.

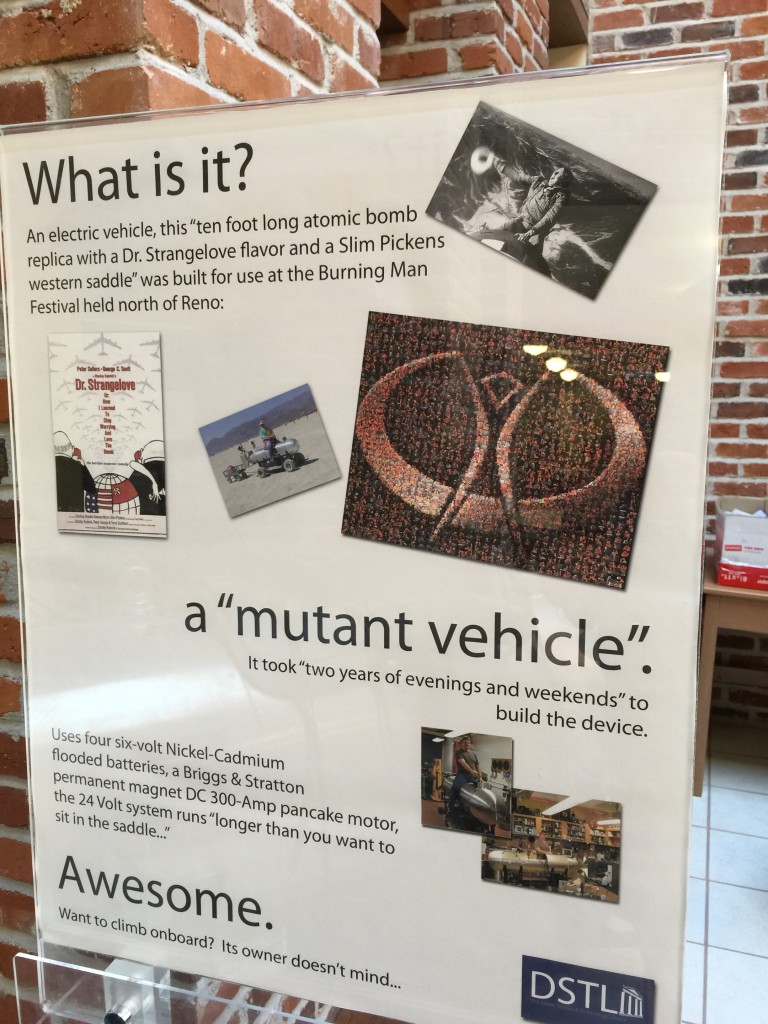

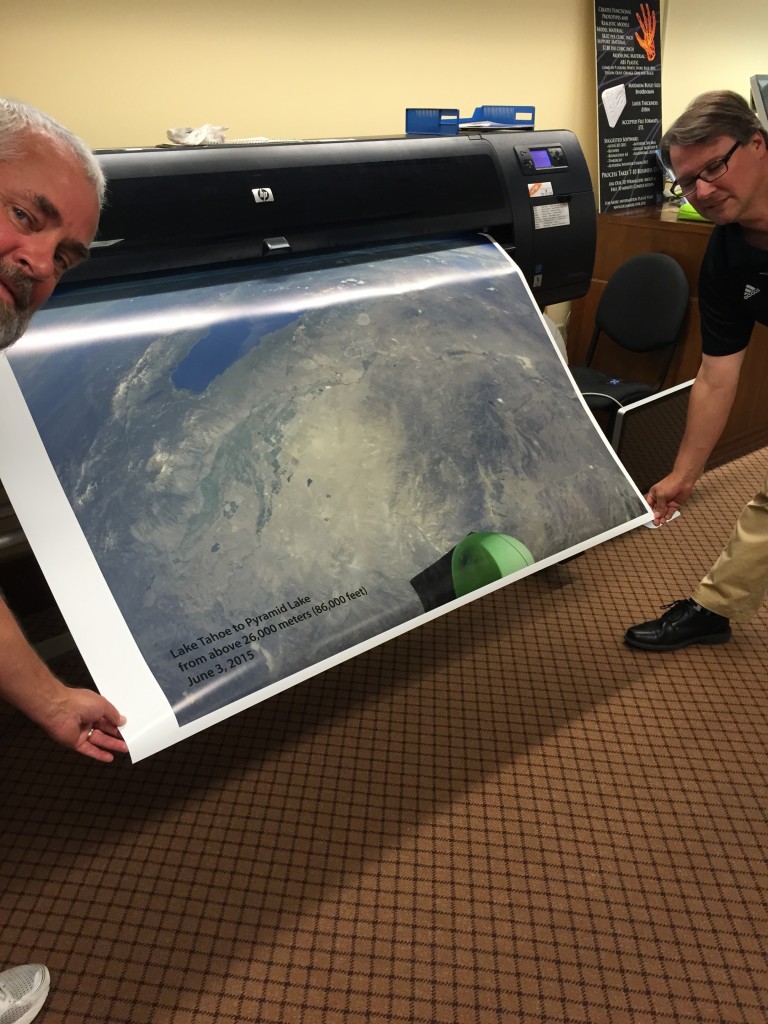

The choice of underwater and aerial vehicles was an easy one … Nevada has been designated one of 5 states where regulations about drones have been eased to encourage research, testing and innovation in drone use (the fact that Nevada contains huge expanses of open land and 4 seasons of weather may have helped). In addition, with the emphasis on encouraging students to study computer programming … and the fact that these vehicles can be programmed … using drones in class to motivate students to engage in both seemed like a perfect match.

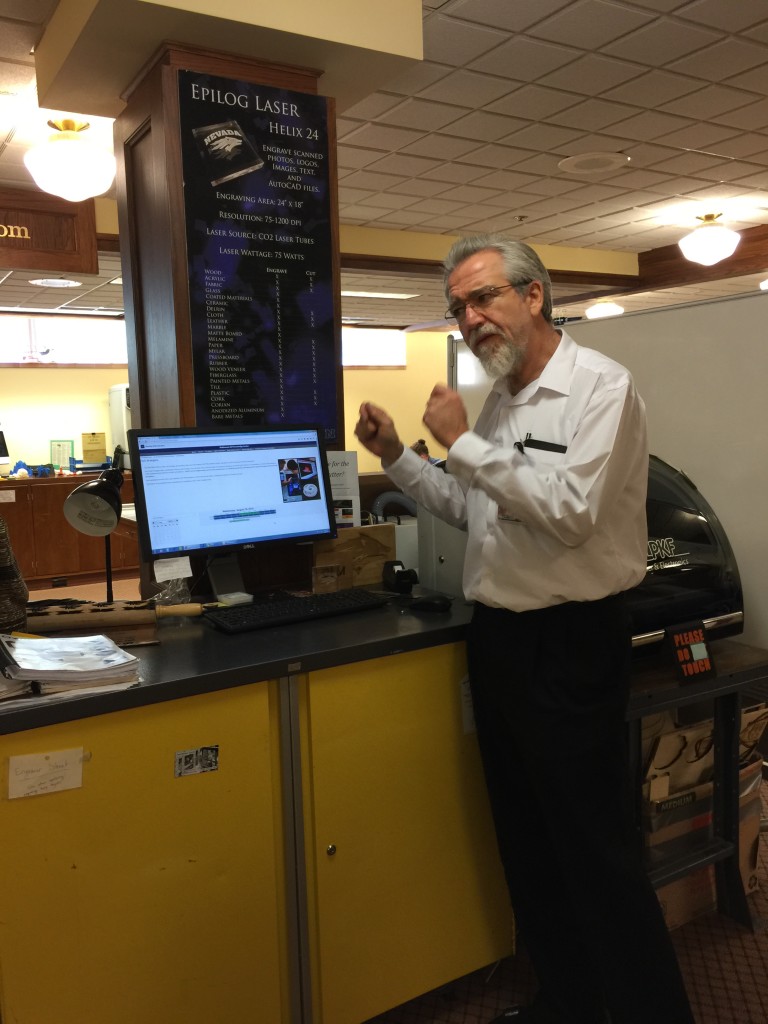

24 teachers, 2 middle school and 2 high school teachers from each of the 6 school districts I serve will be chosen to participate. We will start by doing 2 days of computer programming and 3D modeling utilizing the ncLab online course guided by its developers (a local startup company). Just enough to get teachers started in programming, but also to acquaint them with the online course since it will be available for them and all their students for the next year. I felt that if teachers had even some experience with programming and the online course they would be more likely to use it with their students. Students will have access to the course at school, but also at home or anywhere they can get online, so they can go as far as they like.

24 teachers, 2 middle school and 2 high school teachers from each of the 6 school districts I serve will be chosen to participate. We will start by doing 2 days of computer programming and 3D modeling utilizing the ncLab online course guided by its developers (a local startup company). Just enough to get teachers started in programming, but also to acquaint them with the online course since it will be available for them and all their students for the next year. I felt that if teachers had even some experience with programming and the online course they would be more likely to use it with their students. Students will have access to the course at school, but also at home or anywhere they can get online, so they can go as far as they like.

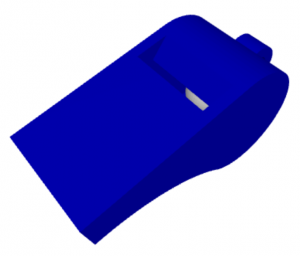

Each teacher will receive a Parrot Minidrone Rolling Spider – the kind you control with your phone or pad device, and a waterproof (to 10 meters) and drop proof (from 1.5 meters) digital camera to archive their learning in the institute and student learning in their classrooms.

Next, teachers will spend 3 days learning about aerial vehicles from Kirk Ellern (a former high school physics teacher) at AboveNV – a local startup. They’ll fly their “Parrots” and learn how to program them (after the institute they’ll have 4 sets of 10 Parrots they can check out for use in their classrooms). After that introduction to aerial vehicles we’ll move on to Phantom 3 Advanced drones. Here we will put the programming we learned (and note what we want to learn more about) in the ncLab course to work. Four sets of three Phantom 3 drones will be available for checkout by participating teachers for use in their classrooms.

use in their classrooms.

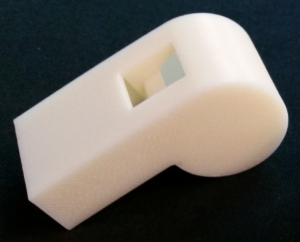

The next 5 days of class will be spent partially assembling and utilizing OpenROV 2.8 underwater vehicles. “Maker skills” will be emphasized as teachers will be taught soldering, wiring, gluing and more to prepare the vehicles for use. 6 OpenROV 2.8’s will be available for checkout by participating teachers. The 2.8’s are operated using a laptop and tether and are capable of depths up to 100 meters. They come with a camera – video/photos and sound can be recorded on the connected laptop … there’s even room for small payloads for doing research – another opportunity to use those computer programming skills as well. Alex Forrest from the Tahoe Environmental Research Center and the University of California, Davis, will lead this portion of the class. Alex has done research in Lake Tahoe utilizing those big “torpedo sized” vehicles you’ve probably seen on the news. He is just back from 3 years in Tasmania.

OpenROV 2.8 Underwater Vehicles

Throughout the school year the course instructors, all specialists in their fields, will be available to consult teachers, visit classrooms and provide follow-up instruction – to me this is a key component of the grant.

Field trip buses will be paid for so participating teachers can take their classes to a water source (lake, pond, wetland, river/stream pool) to operate and do research with the OpenROV’s.

The institute should start up in August and the initial classes will be done by October. I’ll post updates here. I’ll also set up YouTube/Flickr/Wiki and other accounts to archive our progress.

Learning is messy!